Production: Cutting No Corners

production-cutting-no-corners

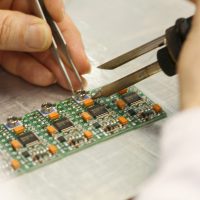

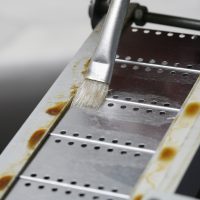

To produce a product with a 0% failure rate* requires a different level of production seldom seen within manufacturing. Firstly, nothing can be done too quickly. Every part of the multi-step process of creating a CYPRES device requires attention to detail and scrutiny with quality control throughout the entire process.

To produce a product with a 0% failure rate* requires a different level of production seldome seen within manufacturing.

This 16-day manufacturing process is the antithesis of Henry Ford’s assembly line of the Model T. Instead our process is more like: Manufacture | Inspect | Manufacture | Inspect | Manufacture | Inspect… continually!

What makes an AAD unique is the owner of the device never knows when the product will be needed. Our job is to ensure that when that time comes, the CYPRES is fully functional regardless of the variables presented. To get that level of reliability requires exhaustive planning, preparation, precision and quality control.

Once the unit comes off the production line, CYPRES will oversee the entire system (processing unit, release unit and control unit) for the entire service life of the device.

* Please see the Legal Disclaimer for further Details

Adventure, Tips, and Adrenaline

Subscribe to Our Newsletter

By signing up for our newsletter you declare to agree with our privacy policy.